50 Ton Air/Hydraulic Shop Press at

T27978 50-Ton Air/Hydraulic Shop Press

For your toughest pressing and stamping needs.

The T27978 50-Ton Air/Hydraulic Shop Press features a fast-pump core that allows the head assembly to lower to the workpiece quicker than a slow-pump core, a hand-operated winch for raising and lowering the bed, and a spring return ram for faster retraction.

The two-speed pump operates the ram at a slow or fast pace to accommodate a wide variety of pressing applications.

The pressure gauge allows the user monitor the ram force as applied to the workpiece using the pump handle.

The winch and pulley system lowers and lifts the work table to accommodate workpieces of different sizes.

Like all Grizzly presses, the T27978 comes with a 1-year warranty which covers parts and assures the unit is free from factory defects.

The T27978 manual was written by our U.S.-based Technical Documentation Department and is packed with useful information. The complete and easy-to-read manual provides full instructions on how to assemble and maintain your shop press.

The Grizzly Customer Service and Technical Support Teams are U.S. based. Parts and accessories for the shop press may be available online and shipped from the Grizzly parts warehouse in Springfield, MO.

SPECIFICATIONS:

- Ram max applied force: 100,000 lbs. (50 tons)

- Ram maximum stroke: 7-7/16

- Ram diameter: 2-1/4

- Maximum distance to table: 39

- Minimum distance to table: 9-1/4

- Hand winch lifting capacity: 1000 lbs.

- Working air pressure: 110-125 PSI

- Bed support pin diameter 1-3/16

- Bed adjustment holes: 8

- Bed adjustment hole spacing: 6 On center

- Hydraulic fluid type: Standard hydraulic jack oil

- Footprint: 39-1/2 L x 27-1/2 W

- Overall dimensions: 51 W x 36 D x 68 H

- Approximate shipping weight: 540 lbs.

FEATURES:

- Pneumatic and hydraulic hand-pump operation

- Winch and pulley system for lifting and lowering work table

- Built-in pressure gauge

- Welded steel frame for maximum rigidity

- Adjustable table accommodates wide variety of operations

- Includes two steel arbor plates

-

Ironton 20-Ton Hydraulic Shop Press06 julho 2024

Ironton 20-Ton Hydraulic Shop Press06 julho 2024 -

DIY 20 Ton Hydraulic Shop Press Made with Scrap Metal And Basic06 julho 2024

DIY 20 Ton Hydraulic Shop Press Made with Scrap Metal And Basic06 julho 2024 -

Press Shop ATL06 julho 2024

Press Shop ATL06 julho 2024 -

J. PRESS STORES06 julho 2024

J. PRESS STORES06 julho 2024 -

SHOP FOX W1680 1-Horsepower 17-Inch Floor Model Drill Press06 julho 2024

SHOP FOX W1680 1-Horsepower 17-Inch Floor Model Drill Press06 julho 2024 -

Shop Presses - Jacks and Hydraulics - All06 julho 2024

Shop Presses - Jacks and Hydraulics - All06 julho 2024 -

Automotive production press shop scene Royalty Free image photo06 julho 2024

Automotive production press shop scene Royalty Free image photo06 julho 2024 -

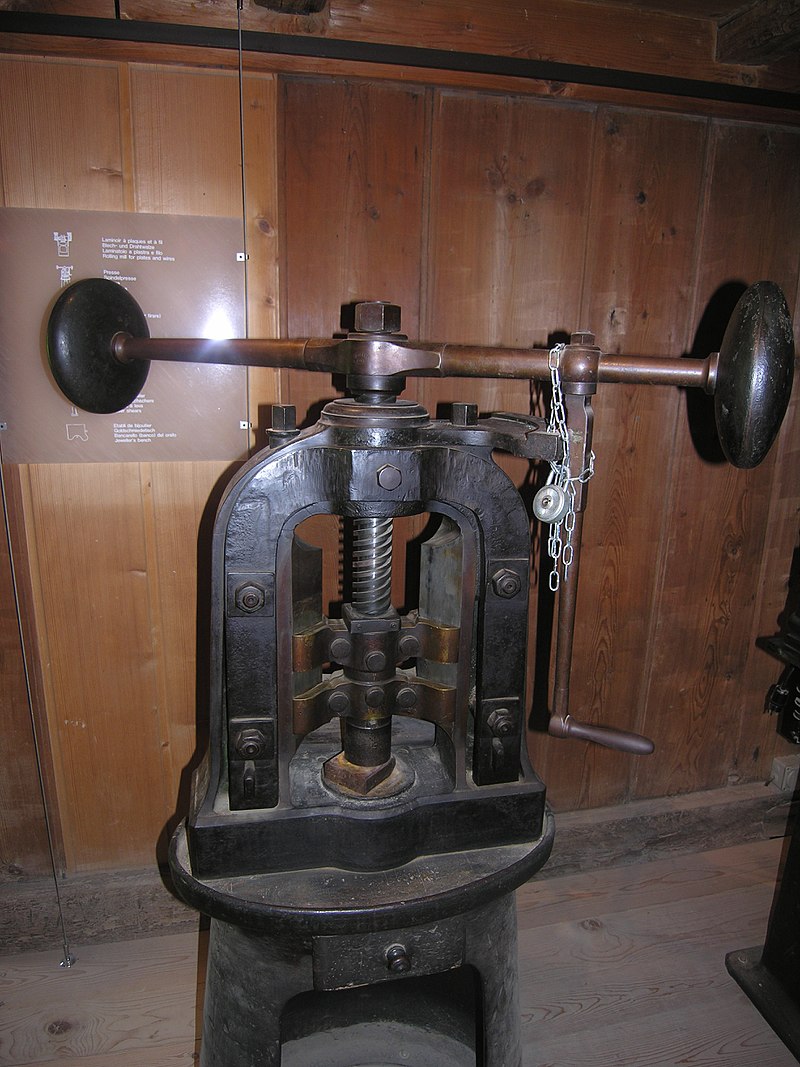

Machine press - Wikipedia06 julho 2024

Machine press - Wikipedia06 julho 2024 -

50 Ton Air Shop Press, Best Shop Press for Sale06 julho 2024

50 Ton Air Shop Press, Best Shop Press for Sale06 julho 2024 -

20 Ton Air/Hydraulic Shop Press w/Gauge - Hydraulic Presses06 julho 2024

-

Create a One Night at Flumpty's (1,2,3 OWaF) characters Tier List - TierMaker06 julho 2024

Create a One Night at Flumpty's (1,2,3 OWaF) characters Tier List - TierMaker06 julho 2024 -

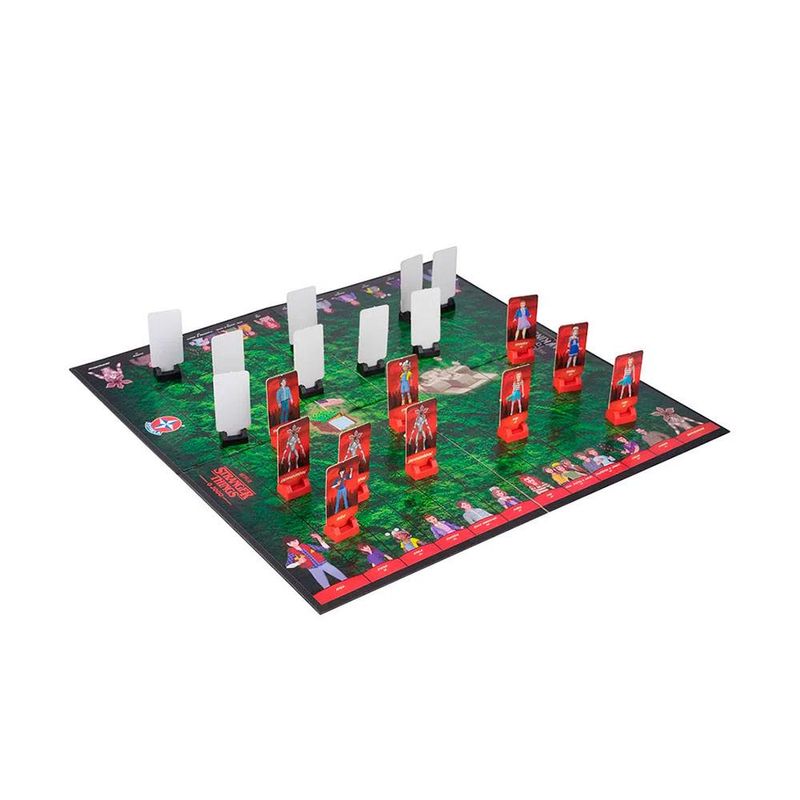

Jogo de Tabuleiro - Stranger Things - Estrela - superlegalbrinquedos06 julho 2024

Jogo de Tabuleiro - Stranger Things - Estrela - superlegalbrinquedos06 julho 2024 -

Ainda acho que o meu é o mais bonito 🤣 #jogos #carros #forza06 julho 2024

-

codigos de reembolso blox fruits 2023|Pesquisa do TikTok06 julho 2024

-

Has scp 999 true form ever been described if so what : r/SCP06 julho 2024

Has scp 999 true form ever been described if so what : r/SCP06 julho 2024 -

NEW* ALL WORKING CODES FOR TOWER DEFENSE SIMULATOR 2023 MAY06 julho 2024

NEW* ALL WORKING CODES FOR TOWER DEFENSE SIMULATOR 2023 MAY06 julho 2024 -

Para chorar de rir: as 7 melhores séries de comédia da HBO Max!06 julho 2024

Para chorar de rir: as 7 melhores séries de comédia da HBO Max!06 julho 2024 -

furukawa nagisa, okazaki tomoya, and okazaki ushio (clannad) drawn by rurounin06 julho 2024

furukawa nagisa, okazaki tomoya, and okazaki ushio (clannad) drawn by rurounin06 julho 2024 -

Mission Craft South American Walnut & Maple Solid Wood Chess Board - 2.25 Squares06 julho 2024

Mission Craft South American Walnut & Maple Solid Wood Chess Board - 2.25 Squares06 julho 2024 -

VELOZ Police 3D APK for Android - Download06 julho 2024

VELOZ Police 3D APK for Android - Download06 julho 2024